Best Practices

Steam System

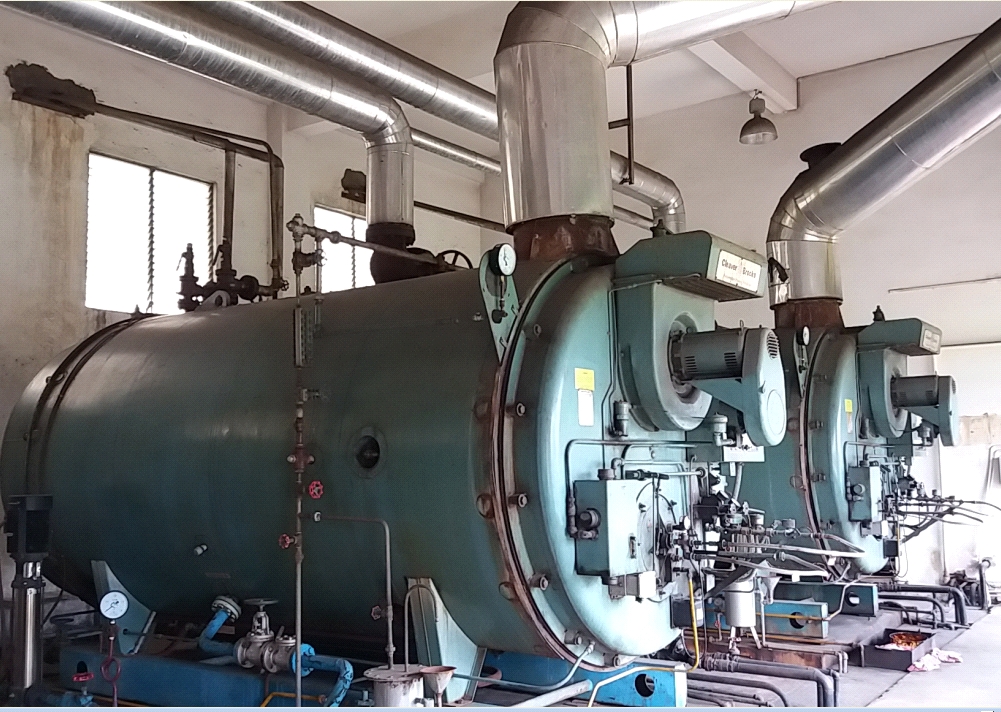

Biofuel boiler

Replacing their seven diesel-driven boilers with biofuel boilers, lowering carbon emissions by almost 100 per cent, or more than 4,000 tonnes annually.

Jiangmen New Star Hi-Tech Enterprise Ltd.Wearing Apparel Manufacturing Industry

Boiler with organic heat carrying agent

Adopting boiler with an organic heat carrying agent which replaces steam with thermally-conductive oil as transmission medium to provide heat energy for production lines. The oil is reheated after returning to the boiler. This change has lowered carbon emissions by more than five per cent or 57 tonnes annually.

Putian Xinfeitian Footwear Co., Ltd.Footwear manufacturing

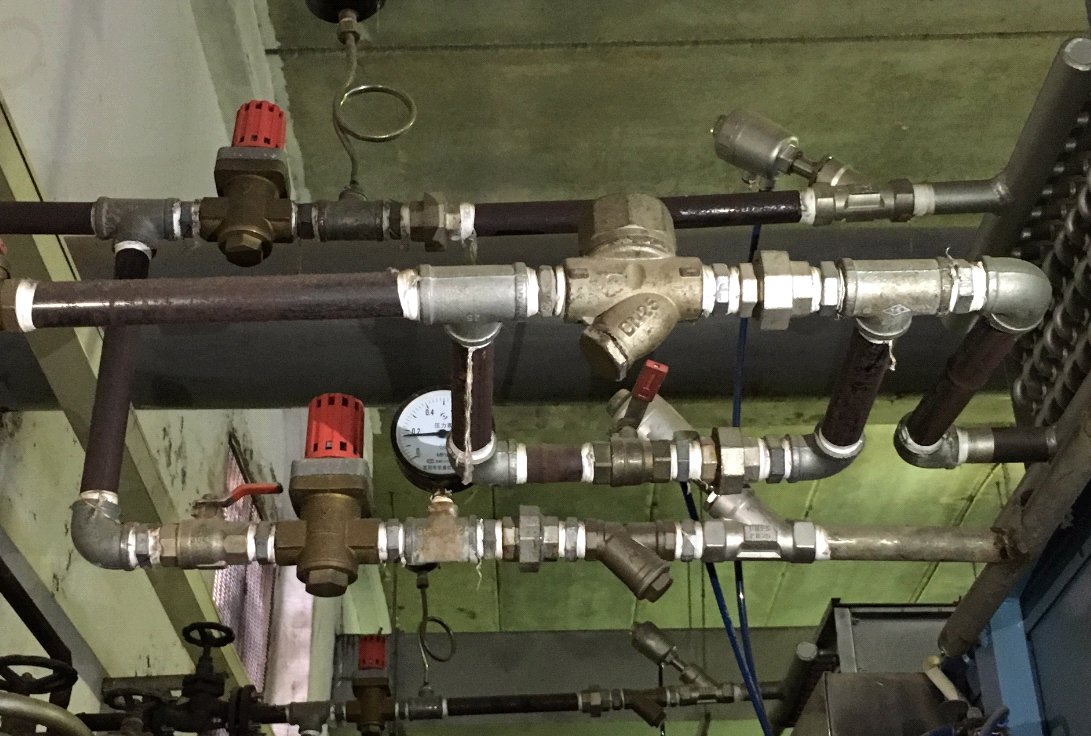

Boiler - Heat recovery system

Boiler system: Installing a heat recovery system, converting energy from exhaust air using a heat exchanger to preheat boiler water.

Ningbo Daye Garden Machinery Co., Ltd.Machinery, equipment, apparatus, parts and components manufacturing

Collection of water condensate

Recovered water condensate from the laundry and dormitory steam system, saving 4,000 tons of steam and reducing annual carbon emissions by more than 1,800 tons.

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Recovering energy from water condensate

Recovering energy from water condensate to preheat water in boilers, reducing energy consumed during the preheating process and hence lowering carbon emissions. The recovery system has saved annual oil consumption by 60 tonnes and has lowered energy consumption by 14%.

Jun Wei Apparel Co., Ltd.Wearing Apparel Manufacturing Industry

Biofuel boiler

Replacing their diesel-driven boilers with biofuel boilers, saving 420,000 liters of diesel annually, lowering carbon emissions by almost 100%, or more than 1,100 tonnes annually.

Regent Garment Factory Ltd.Wearing Apparel Manufacturing Industry

Heat recovery from steam and condensate

Installing a hot water tank and pipeline to utilize return steam and condensate water from garment dryers for heating water in washing machines, saving 14,700 tonnes of steam monthly.

Regent Garment Factory Ltd.Wearing Apparel Manufacturing Industry

“Circulating fluid bed” Boiler

Replacing its “chain grate boilers” with “circulating fluidized bed boilers” which have more efficient energy usage, desulfurization and NOx emission reduction capability

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Textile Industry

Boiler using natural gas

Changing the type of fuel used in their boiler from diesel to natural gas resulting in a reduction of annual carbon emissions by 142 tonnes.

Shenzhen Hong Tao Non-Woven Fabric Co., Ltd.Textile Industry

Replace steam traps in drying machines and steam irons

By replacing steam traps in drying machines and steam irons, minimizing boilers’ heat loss due to aging of the traps, reducing the number of operating boilers from two to one, resulting in an annual saving of 240 tonnes of fuel oil.

Jun Wei Apparel Co., Ltd.Wearing Apparel Manufacturing Industry

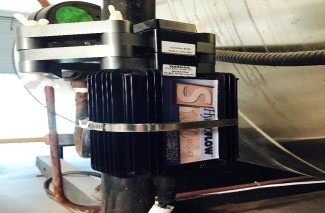

Electromagnetic wave scale deposit processor

Installing an electromagnetic wave scale deposit processor in boilers has reduced the deposit’s adhering to the inner wall of boiler pipes, thereby improving the energy efficiency of the boiler, resulting in carbon emissions reduction of 32 tonnes annually.

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Heat insulated steam pipes

insulated its steam pipes to prevent heat loss

K+K Fashion Company LimitedWearing Apparel Manufacturing Industry

Installation of individual switches on washing machines’ steam pipes

Placed individual switches on its washing machines’ steam pipes to avoid unnecessary steam loss

K+K Fashion Company LimitedWearing Apparel Manufacturing Industry

Replacement of diesel boiler with natural gas-fired steam engines

Replacing a 2t/h diesel boiler with two 0.6t/h natural gas-fired steam engines. These are more efficient and have reduced annual natural gas consumption by about 65,000 m3

Jiangmen Anotech Cookware Manufacturing Company Ltd.Fabricated Metal Industry

Retrofitting thermal insulation on steam pipelines

Retrofitting thermal insulation on steam pipelines in workshops, using aluminium silicate fibre wool and rock wool with coloured steel plate wrapping. These substances are excellent thermal insulators, as well as being aesthetically pleasing and durable. Energy and steam loss from the pipes was reduced from 30-40 per cent and 15 per cent per kilometre before the retrofit, to 15-20 per cent and 6 per cent per kilometre after the retrofit. This has saved 36,800 tonnes of steam and lowered carbon emissions by about 9,627 tonnes annually.

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Wearing Apparel Manufacturing Industry

Installation of modern boiler with economiser

Planning to replacing current steam boilers with modern ones that include an economiser, achieving an overall heat efficiency of 93% and reducing natural gas consumption by 17%. This will save 1.55 million m3 of natural gas per year and lower annual carbon emissions by 3,246 tonnes

Queen South Textile Mills LimitedWearing Apparel Manufacturing Industry

Installation of waste heat recovery devices in generators and boilers

Installing waste heat recovery devices in generators and boilers. In natural gas generators, the devices transfer waste heat at 400°C to the boilers used for ironing. The boilers’ economisers then recover residual heat in the flue gas, which is then used for pre-heating. This recovered heat supplies more than 90% of the heat needed for ironing – about 30% of CMBD’s total operational energy. This reduces boiler diesel costs by about US$216,000 and cuts carbon emissions by 750 tonnes annually.

Crystal Martin Apparel Bangladesh Ltd.Wearing Apparel Manufacturing Industry