Best Practices

Manufacturing Processes

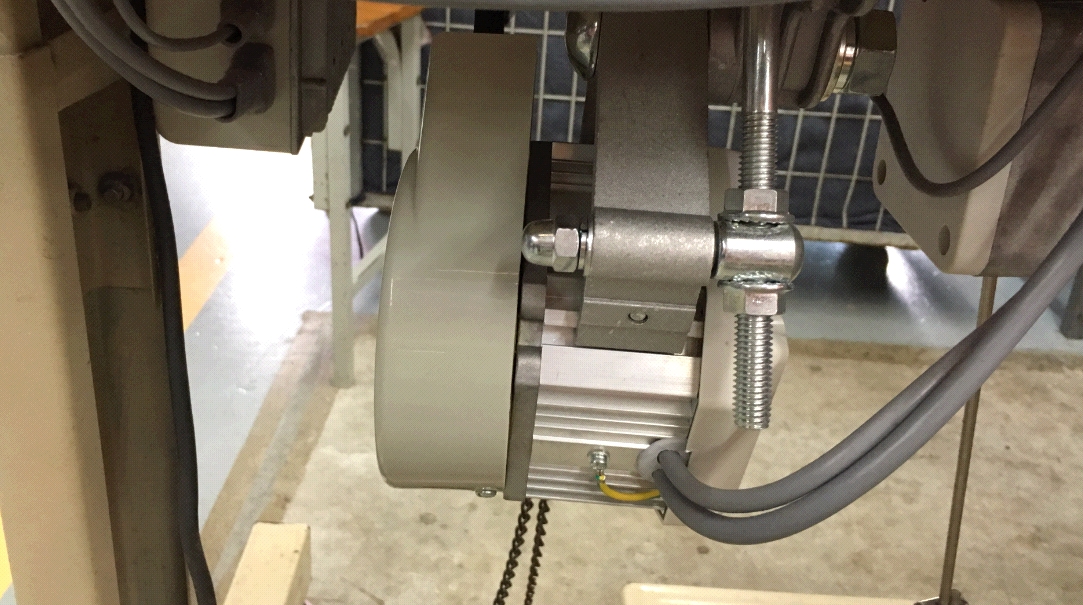

Linking machine with energy saving motor

DC energy saving servo motors were installed in the linking machine, enhancing the utilization of electricity to more than 90 per cent. These servo motors have a payback period of 18 months and have reduced annual electricity consumption by more than 460,000 kWh and have lowered carbon emissions by more than 50 per cent.

Dongguan Yeji Industrial Company Ltd.Wearing Apparel Manufacturing Industry

Closed-loop high-efficiency dryers

Closed-loop high-efficiency dryers with multiple energy saving features were installed. These features include microcomputer controllers and heat recovery installations, and have reduced drying time by 50 per cent and increased energy savings by 34 per cent. These dryers have a payback period of 12 months and save more than 1,800 tonnes of steam annually.

Dongguan Yeji Industrial Company Ltd.Wearing Apparel Manufacturing Industry

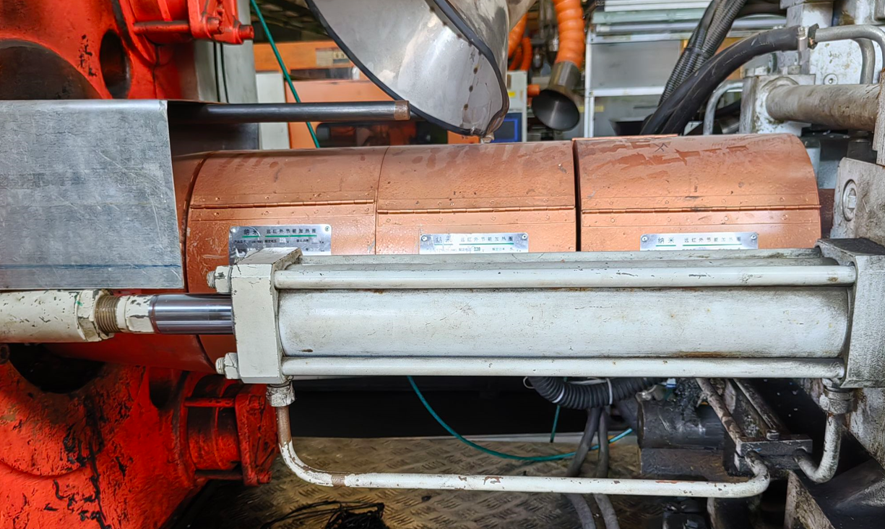

Electro-magnetic induced Extrusion machine

Replacing electro-resistance heating with electro-magnetic induction on extrusion machines, reducing energy use by more than 35 per cent.

Ningbo Helong New Material Co., Ltd.Wood Plastic Composite Manufacturing Industry

Hanging system on drying machines

Installing a hanging system on drying machines which uses waste heat to preheat washed jeans. The system greatly reduces the jean’s water content and lowers steam usage of drying machines by 50 per cent.

Changzhou Baolai Garments Co., Ltd.Wearing Apparel Manufacturing Industry

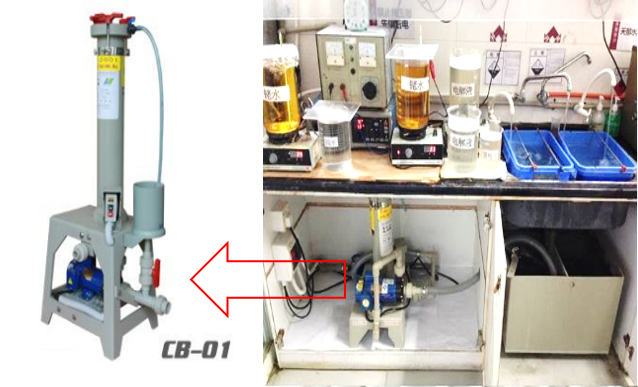

Waste water recycling tank

Recycling industrial waste water through biochemical treatment, with a recycling efficiency of up to 80 per cent.

Positec Machinery (China) Co., Ltd.Machinery, equipment, apparatus, parts and components manufacturing

Capacitor storage welding machine

Using capacitor discharge rowing welding machines to save electricity, efficiently utilizing stored current and increasing output at the same time.

Guangdong Atlan Electronic Appliance Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

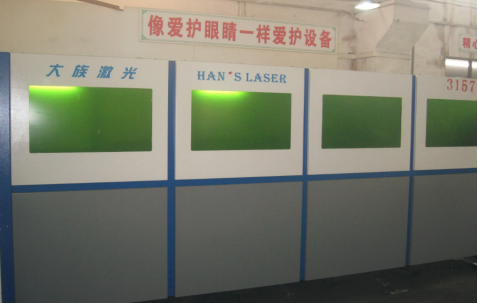

Laser cutting machine

Adopting laser cutting machines to improve cutting quality and reduce the frequency of mould-making, creating both energy and cost savings.

Guangdong Atlan Electronic Appliance Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

Welding robot arm

Adopting an automatic robot welding arm, improving quality and raising productivity in the welding process.

Guangdong Atlan Electronic Appliance Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

Energy saving knitting machines

Investing more than HK$300M in auto-knitting machines, increasing their productivity by more than 30 per cent, and reducing their electricity usage and carbon emissions by more than 40 and 50 per cent respectively.

Super Performance Textile (Shenzhen) Co., Ltd.Wearing Apparel Manufacturing Industry

Automatic hanging system

Designing an automatic garment hanging system, increasing productivity and improving process flow, ultimately leading to lower carbon emissions.

Super Performance Textile (Shenzhen) Co., Ltd.Wearing Apparel Manufacturing Industry

Drying lines modification

Shortened the length of 10 drying production lines in the assembly process from ten metres to six metres, reducing annual electricity consumption by 24 per sent (equivalent to 151,800 kwh) and lowering carbon emissions by more than 110 tonnes annually.

Zhejiang Shenghui Lighting Co., Ltd.Electrical Appliances and Houseware Industry

Temperature controlled soldering iron

Replacing traditional soldering irons without temperature controls with energy saving irons which allow the regulation of temperature within a preset range during operation.

Dayssan Lighting Industrial Ltd.Electrical Appliances and Houseware Industry

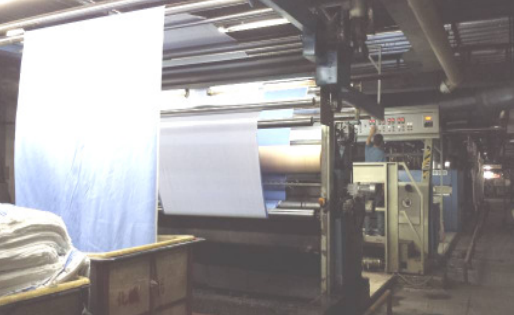

Stenter operated by steam

Replaced thermal oil with high pressure steam as transmitting medium to power the heat exchanger. This provides more efficient heat transmission to the stenter. Water condensate from the steam can also be recovered to provide heat energy for production lines and the electricity generating facility – this change has lowered carbon dioxide emissions by more than 6,200 tonnes annually.

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Textile industries

Cold bleaching pretreatment

Replaced their traditional steam generated “Hot Bleaching” pretreatment process with a “Cold bleaching – Short steam – Water rinse” approach in their knitted fabric facility – lowering carbon dioxide emissions by more than 600 tonnes annually.

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Textile industries

Automated LED production line

Adopting automation in their LED production line to increase productivity.

Leedarson Lighting Co., Ltd.Electrical Appliances and Houseware Industry

Store room – zone control

Establishing zone control and stock management procedures in the store room for better resource utilization.

Leedarson Lighting Co., Ltd.Electrical Appliances and Houseware Industry

Aging line - baffles

Aging line: Installing high efficiency motors and adding baffles at both sides to reduce heat loss at the entrance.

Leedarson Lighting Co., Ltd.Electrical Appliances and Houseware Industry

Injection molding - servo control

Injection molding machines:Adopting servo & proportional control, adjusting cooling water temperature by automatic controls.

Ningbo Daye Garden Machinery Co., Ltd.Machinery, equipment, apparatus, parts and components manufacturing

Solar energy for the production lines

Replaced steam with solar energy, providing heat to the dormitory and production line, reducing steam consumption by 75 percent and lowering annual carbon emissions by more than 1,100 tons.

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industryg

Forging process operated by natural gas

Changing kerosene pipelines into natural gas pipelines in forging process.

Zhejiang Pleast Sanitary Ware Co. Ltd.Fabricated Metal Industry

Automatic robot welding arms

Improve quality and raise productivity in the welding process

Guangdong Atlan Electronic Appliance Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

Capacitor discharge rowing welding machines

Efficiently utilize stored electric current and increase productivity to save electricity

Guangdong Atlan Electronic Appliance Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

Laser cutting machines

Improve cutting quality and reduce the frequency of mould-making hence create both energy and cost savings

Guangdong Atlan Electronic Appliance Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

Staff notice board

Promote company policy and strengthen communication with management and staff

Guangdong Atlan Electronic Appliance Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

Automatic hanging system

Centralize the production processes, reduce transportation distance and hence increase productivity

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Regular monitoring for production processes

Appropriate and regular monitoring for production processes can enhance product quality and reduce scrap rate

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Servo motors in sewing machines

Reduce electricity consumption by adopting servo motors in sewing machines

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Install LED lamps in sewing machines

Reduce electricity demand of the nearby lighting system

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

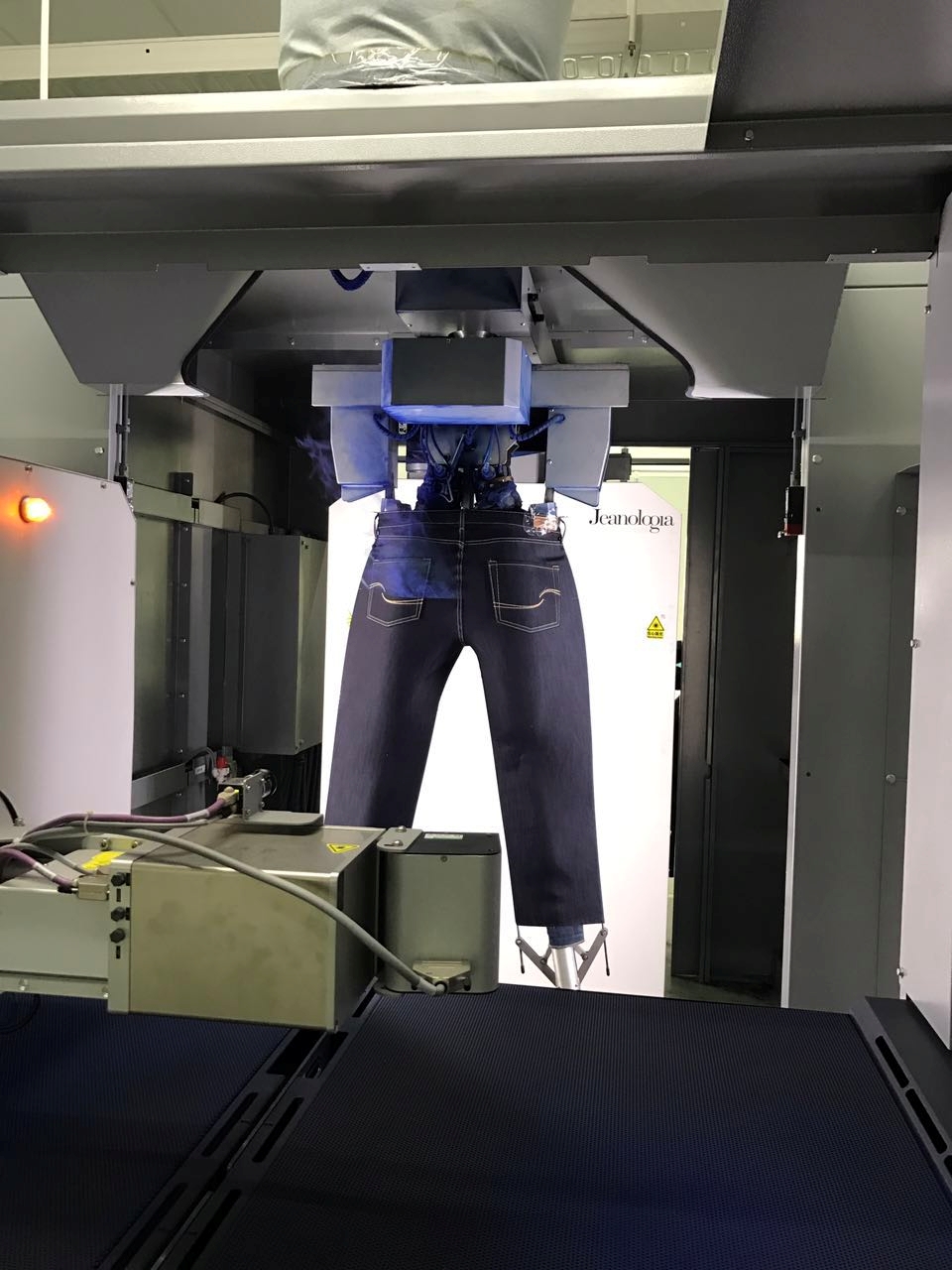

Laser embroidery

Adopt laser embroidery to carve patterns on jeans, avoid usage of chemicals and provide versatile design

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Energy saving drying machines

Reuse hot exhaust air, automatically adjust the air supply amount and hence reduce electricity consumption

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Automatic hanging system (Pre-dry)

Pre-drying by ambient heat in automatic hanging system, reduce the electricity consumption of drying machines

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Ozone bleaching

Extract ozone from air for bleaching, no water and bleaching agent are required, making bleaching process more environmentally friendly

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Wastewater treatment system

Reduce sewage discharge and comply with environmental ordinances

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

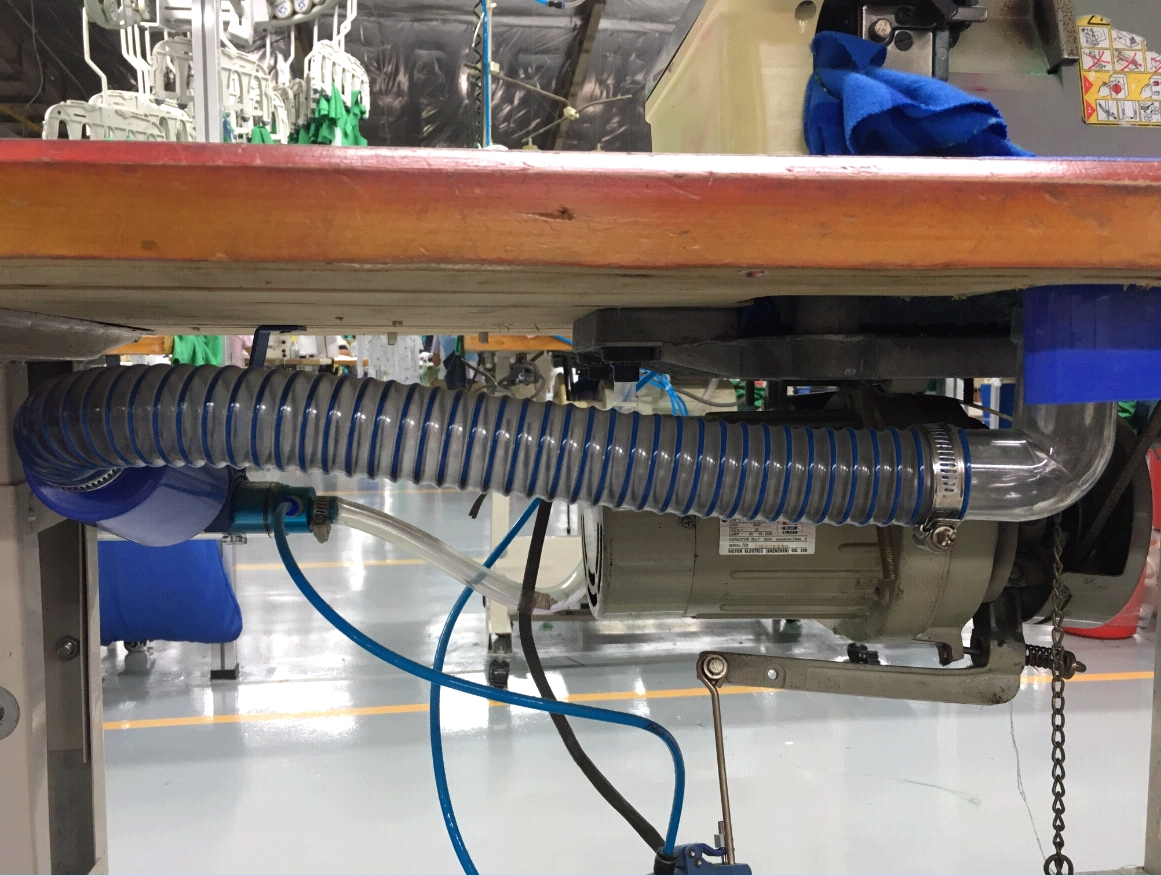

Heat Recovery for injection moulding machine dryer units

Installing heat recovery ducts in 20 injection moulding machine dryer units. The ducts recycle waste heat from the dryer exhaust to dry the raw materials, reducing the factory’s annual electricity consumption by about 190,000 kWh.

Nexus Electrical (Jiaxing) LimitedElectrical Appliances and Houseware Industry

Variable frequency Drives in washing machines and dehydrators

Installing Variable frequency drivers (VFDs) in washing machines and dehydrators, reducing the overall average power. The VFDs have saved annual electricity consumption per machine by 1,500 and 6,000 kWh respectively, and have lowered energy consumption by 25% and 63% respectively.

Jun Wei Apparel Co., Ltd.Wearing Apparel Manufacturing Industry

Servo motoring system on metal casting machines

Replacing hydraulic system with servo motoring system on metal casting machines, with a 12-month payback period. The change has reduced electricity consumption by more than 40% and lowered annual electricity consumption by 600,000 kWh.

Leo Group Co., Ltd.Machinery, Equipment, Apparatus and Components Industry

Servo drivers and plunger pump on injection molding machines

Replacing variable displacement pump with servo drivers and plunger pump on injection molding machines, reducing electricity consumption by more than 20%.

Leo Group Co., Ltd.Machinery, Equipment, Apparatus and Components Industry

Electric-powered forklifts

Adopting electric-powered forklifts in factory area and recycling waste batteries, lowering carbon emissions by 60 tonnes annually.

Leo Group Co., Ltd.Machinery, Equipment, Apparatus and Components Industry

DC energy saving servo motors in sewing machines

Installing DC energy saving servo motors in the factory’s sewing machines, enhancing the electricity utilization rate to over 79 per cent. These servo motors are expected to reduce K+K’s annual electricity consumption by 380,000 kWh and lower carbon emissions by more than 250 tonnes annually.

K+K Fashion Company LimitedWearing Apparel Manufacturing Industry

Suck thread ends by compressed air in sewing machines

Using compressed air to suck thread ends in the sewing machines instead of electric motors. This change is expected to reduce annual electricity consumption by 35 per cent and lower annual carbon emissions by more than 70 tonnes.

K+K Fashion Company LimitedWearing Apparel Manufacturing Industry

Automatic cutting machines

Using automatic cutting machines to improve the accuracy of cutting and hence reducing the defect rate and saving labour costs

Maxturn Apparel Company LimitedWearing Apparel Manufacturing Industry

Laser embroidery machines

Adopting laser embroidery machines to make patterns on fabrics, reducing water and energy consumption by 60 per cent and chemical consumption by 85 per cent

Changzhou Baolai Garments Co., Ltd.-Wearing Apparel Manufacturing Industry

Ozone bleaching machine

Installing a chemical free ozone washing machine to produce bleaching effects, saving a huge amount of water and reducing production time

Changzhou Baolai Garments Co., Ltd.-Wearing Apparel Manufacturing Industry

Dye-Wash machine

Installing combined dye-wash machines, mixing raw materials and chemical additives into a nano-state by centrifugal pumps, not only reducing water and chemical consumption but also increasing productivity

Changzhou Baolai Garments Co., Ltd.-Wearing Apparel Manufacturing Industry

Hydrocarbon vacuum cleaning machine

Replacing its traditional manual cleaning method for gears and worms with a hydrocarbon vacuum, which reduces polluting emissions, saves 5,400 litres of cleaning agent annually and increases productivity by a factor of 3.8.

Spintec Precision (Shenzhen) Ltd.Fabricated Metal Industry

Energy saving Setting Machine

Installing Setting Machines with a heat recovery feature, reducing annual energy consumption by more than 15 per cent and standard coal consumption by 300 tonnes

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Textile Industry

Continuous shrinking machine

Installing a new continuous shrinking machine, which increases annual production capacity while reducing steam consumption and standard coal consumption by 450 tonnes.

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Textile Industry

Washing machine with nanotechnology

The application of nanotechnology in its washing machines to soften apparel and evaporate water during the drying process, resulting in a 97 per cent reduction in water usage (with zero wastewater), an 88 per cent reduction in chemical usage, a 43 per cent reduction in steam, and a 21 per cent reduction in electricity consumption. In total, this allowed the company to avoid 155 tonnes of carbon emissions annually.

Dongguan Crystal Knitting and Garment Co., Ltd.Wearing Apparel Manufacturing Industry

Redesign switch structure of drying lamp tubes in printing section

By reducing the number curing lamps controlled by each switch used in printing from 4 to 1 (and only turning on the necessary lamps) the company achieved a 22 per cent (or 240,000 kWh) annual reduction in electricity usage. This equates to 163 tonnes of avoided carbon emissions.

Dongguan Crystal Knitting and Garment Co., Ltd.Wearing Apparel Manufacturing Industry

Centralized LPG piping system

Changing the LPG delivery method saved 290,000 kWh of electricity consumption and reduced LPG usage by 2,775 m3 annually. This was achieved by replacing bottled LPG delivery with a gasification system with centralized piping. This also solved the LPG residue loss and storage safety issues that occur with bottle delivery.

Dongguan Crystal Knitting and Garment Co., Ltd.Wearing Apparel Manufacturing Industry

Water recycling facilities

By using recycled treated wastewater on production lines and for planting / toilet flushing, the overall water consumption was reduced by 50 per cent and 15 per cent respectively.

Super Performance Textile (Shenzhen) Co., Ltd.Wearing Apparel Manufacturing Industry

Adoption of brushless motors in sewing machines

By replacing clutch motors with energy efficient brushless motors in sewing machines, they have improved motor idling issues, increased motor life expectancy and reduced motor noise, reduced electricity consumption by 60-75 per cent and saved about 640 kWh annually for each sewing machine.

Jun Wei Apparel Co., Ltd.Wearing Apparel Manufacturing Industry

Variable frequency control system in punching machine

Installing variable frequency control system in punching machines, reducing electricity consumption in each stages of the punching cycle.

Jiangmen New Star Hi-Tech Enterprise Ltd.Fabricated Metal Industry

Auto-welding and auto-brushing machines

Adopting auto-welding and auto-brushing machines to replace the traditional manual workmanship, enhancing productivity and product quality.

Jiangmen New Star Hi-Tech Enterprise Ltd.Fabricated Metal Industry

Electric forklift

Replacing diesel forklift with electric forklift, reducing carbon emissions and improving air quality.

Jiangmen New Star Hi-Tech Enterprise Ltd.Fabricated Metal Industry

Install hanging system and recover heat from condensate to enhance drying effect.

From the early stage of only using dryers for drying jeans to a previous stage of hanging washed jeans above dryers and making use of waste heat to dry the jeans, they have progressed to recent installation of a semi-closed tunnel to collect heat from condensate via heat transfer devices to further absorb heat for drying purposes. This saves 130 tonnes of steam and reduces carbon emissions by 20 tonnes annually.

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Heat collection from condensate in dryers

Hot air normally enters dryers from the top. To enhance drying, the factory installed energy saving steam boxes to collect heat from condensate, this enters the dryer at the front resulting in better heat utilization. This not only reduces drying time by 23 per cent, but also saves 1,360 tonnes of steam and reduces carbon emissions by 208 tonnes annually.

ZhongShan Yida Apparel Ltd.Wearing Apparel Manufacturing Industry

Replace oil-based paint with water-based paint

Replacing oil-based paint with water-based paint for printing has reduced the amount of dilutant required and improved the workshop environment.

Foshan Longart Building Decoration Materials Co., Ltd.Building Materials Industry

Replace spray painting with UV ink printing

Replacing spray painting with UV ink printing, plus reducing a large amount of thinner used in spray painting and improving the workshop environment

Foshan Longart Building Decoration Materials Co., Ltd.Building Materials Industry

Heat recovery from Kiln

Recycling waste heat from the kiln, providing heat to replace the heat supply from electric-driven heaters in the “meshing pasting” process.

Foshan Longart Building Decoration Materials Co., Ltd.Building Materials Industry

Thermal insulation coatings on SMT reflow machine surface

Coating thermal insulation material on surface of SMT reflow machines and preventing heat escape from reflow chambers to the workshop. This not only reduces power consumption by avoiding continuously raising the temperature due to heat loss in reflow machines, but also reduces cooling needs in the workshop. This helps reduce annual electricity consumption by about 370,000 kWh and lowering carbon emissions by about 243 tonnes annually.

Ningbo Klite Electric Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

Optimization on laminating machine rollers

Optimizing the laminating machine in the material cutting workshop from simultaneous heating of the upper and lower rollers to only heating the lower roller, this not only reduces power consumption by a half but also lowers the workshop temperature near laminating machines. This helps reduce annual electricity consumption by about 47,000 kWh and lowering carbon emissions by about 25 tonnes annually.

Martin Emprex Textiles (Zhongshan-China) Ltd.Wearing Apparel Manufacturing Industry

Multi-stations molds for stamping dies

Adopting a continuous operation approach for stamping dies, transforming manual operation of single-station molds into continuous operation of multi-stations molds with robotic arm automatic loading, reducing the number of stamping work stations and running time, improving productivity and saving about 2 million RMB annually.

Luceco Electrical (Jiaxing) Co., Ltd.Electrical Appliances and Houseware Industry

Optimisation of spray painting process parameters

Optimising the spray painting process parameters, reducing spray powder coating thickness and workpiece heating time, increasing transmission chain cycling frequency and the plastic powder recycling rate, saving about $500,000 RMB annually.

Luceco Electrical (Jiaxing) Co., Ltd.Electrical Appliances and Houseware Industry

Reformation of testing equipment combinations

Reforming testing equipment combinations, combining product safety testing, mechanical function testing, code-spurting and other related processes at the same facility, reducing running time and increasing productivity, saving about $500,000 RMB annually.

Luceco Electrical (Jiaxing) Co., Ltd.Electrical Appliances and Houseware Industry

Display energy saving knowledge in production notice board

Enhancing employees’ energy-saving and carbon emissions reduction knowledge by displaying related information on bulletin boards in the workshop area

PY Garment Manufacturing (Rongxian) Company LimitedWearing Apparel Manufacturing Industry

Computerised storing quality inspection records

Storing quality inspection records in a computerised system instead of paper records and reports, reducing paper consumption and facilitating data storage

PY Garment Manufacturing (Rongxian) Company LimitedWearing Apparel Manufacturing Industry

Infra-red heaters on extrusion machines

Replacing electro-magnetic induction/electro-resistance heating with infra-red on extrusion machines, reducing electricity consumption by 25 per cent

Ningbo Helong New Material Co., Ltd.Wood Plastic Composite Manufacturing Industry

Developing recycled wood-plastic products

Developing recycled wood-plastic products to minimise deforestation, using recycled materials and reusing scrap products to reduce wastage of resources

Ningbo Helong New Material Co., Ltd.Wood Plastic Composite Manufacturing Industry

Adopting electric transport cars and forklifts

Adopting electric transport cars and forklifts, reducing carbon emissions from burning fossil fuels

Ningbo Helong New Material Co., Ltd.Wood Plastic Composite Manufacturing Industry

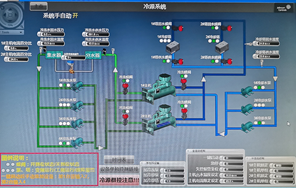

Structure Energy Efficiency Dashboard (SEED)

SEED is a building energy efficiency analysis software system, which helps analyse and evaluate energy consumption through data charts, reports and statistical analysis tools. It provides flexible design settings for maintenance plan set-up. SEED helps Martin Emprex manage its centralised air-conditioning system, monitor the electricity consumption for lighting systems and production facilities, and provides feedback on water consumption data. The system helps the factory detect abnormal energy consumption patterns, embed best energy management practices in day-to-day operations, and improve energy efficiency by eliminating energy waste.

Martin Emprex Textiles (Zhongshan-China) LimitedWearing Apparel Manufacturing Industry

Automated Guided Vehicles (AGV)

AGV robot system is an automated material receiving and dispatching system in factory’s raw material warehouse. The system customarily collects and dispatches materials from designated point to point upon inputting command. Martin Emprex utilises AGV to improve productivity, reduce transportation distance, increase storage space, avoid human error and improve workplace safety.

Martin Emprex Textiles (Zhongshan-China) LimitedWearing Apparel Manufacturing Industry

Heat Recovery from Pre-shrinking Machine

Waste heat generates from the Pre-shrinking machine will be recycled and to preheat water for boiler, this can save annual electricity consumption by about 18,000 kWh and reduce carbon emissions of about 9 tonnes respectively.

Martin Emprex Textiles (Zhongshan-China) LimitedWearing Apparel Manufacturing Industry

Connecting vacuum pumps pipelines

Connecting the pipelines of all vacuum pumps in the zipper workshop together. Previously, each individual vacuum pump was fixed with an individual machine – now that the pipelines are connected resulting less vacuum pumps are used. This has reduced annual electricity consumption by about 23,000 kWh and carbon emissions by around 12 tonnes.

Huizhou Yiji Garment Accessories Co., Ltd.Fabricated Metal Industry

Installation of energy saving device on friction press machine

Reducing the power consumption of the friction press machine - A device that forms cookware into various shapes by putting different materials under high pressure of 1600-2500T. Anotech installed an energy saving device that reduces the speed of the machine’s flywheel during idle or standby mode, reducing electricity consumption by about 30 per cent.

Jiangmen Anotech Cookware Manufacturing Company Ltd.Fabricated Metal Industry

Replacing manual sanding machines with automatic ones

Replacing manual sanding machines with automatic ones, increasing the monthly production output from between 800 and 1000 sides per operator to 1200-1300 sides per machine, and allowing multiple machines to be managed by one operator. This has enhanced their production capacity by 25 per cent, improved the work environment and decreased occupational hazards.

Jiangmen Anotech Cookware Manufacturing Company Ltd.Fabricated Metal Industry

Nano-coating “aqua print through advanced textiles” process & new finishing technologies

Developed an “aqua print through advanced textiles” process using nano-coating and new finishing technologies to eliminate the steaming and rinsing involved in traditional screen printing. This dramatically cuts down on steam and water consumption and reduces the carbon emissions of the entire product by about 43.7%.

High Fashion (China) Co., Ltd.Wearing Apparel Manufacturing Industry

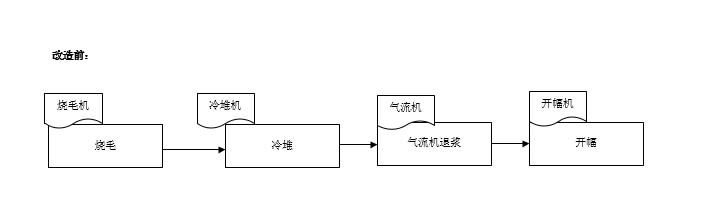

Production processes optimization

Optimised production processes in several ways – installed grooves to integrate the singeing and cold heap processes; adopted a continuous annealing bleaching machine to replace the original independent processes; desizing performed by an air flow dyeing machine; open widthing performed by an open width machine; and drying done by a setting machine. Together, these processes can improve productivity and reduce carbon emissions by about 63%.

High Fashion (China) Co., Ltd.Wearing Apparel Manufacturing Industry

Recycling rinse water used in the gold plating process

The gold plating process uses large amounts of water during the rinsing part of the process. This factory recycles rinse water by using a filtration system, reducing water consumption by around 1,000 cubic metres.

Chow Tai Fook Jewellery Culture Industrial Park (Wuhan) Company LimitedFabricated Metal Industry

Reduction of waste acids and alkalines

Jewellery production processes generate huge amounts of waste acids and alkalines. The installation of a neutralisation treatment system helps the factory fulfil discharge water standards, reducing annual hazardous waste production by about 80 tonnes.

Guangdong Shunde Chow Tai Fook Jewellery Manufacturing Co., Ltd.Fabricated Metal Industry

Automation on production facilities

Automating their assembly lines, increasing productivity by about 30 per cent and reducing the carbon emissions of each watch by about 50 per cent compared to the base year.

Greenland Watch LimitedElectrical Appliances and Houseware Industry

Energy-saving dyeing machine

Replacing traditional ECO-6 dyeing machines with 16 new energy-saving TEC-WIN machines with a higher production capacity, lower bath ratio and intelligent controls. The peculiar design of the fan and nozzle also improves the crease issue. This has reduced water consumption by 38 per cent and electricity consumption by 37 per cent, saving 1.47 million kWh of electricity and 27,200 tonnes of steam annually, lowering yearly carbon emissions by about 9,575 tonnes.

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Wearing Apparel Manufacturing Industry

Energy-saving setting machine

Purchasing eight new energy-saving setting machines that improve the shrinkage rate, fabric flatness and weight uniformity. These have reduced annual electricity and medium-pressure steam consumption by about one million kWh and 15,600 tonnes respectively, lowering annual carbon emissions by approximately 6,227 tonnes.

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Wearing Apparel Manufacturing Industry

Replacement of traditional asynchronous motors with first-class energy efficient & permanent magnet synchronous motors

Replacing traditional asynchronous motors with different pieces of equipment, such as rotary screen printing machines, lithium-bromide centralised air-conditioning and air compressors with first-class energy efficient and permanent magnet synchronous motors. These have reduced annual electricity consumption by 244,200 kWh and lowered carbon emissions by 142 tonnes per year

Dongguan Shatin Lake Side Textiles Printing & Dyeing Co., Ltd.Wearing Apparel Manufacturing Industry

Installation of automatic warehouse system

Installing an automatic warehouse system with 16 levels and 2,289 storage locations. This enables raw materials to be automatically transported to storage and production areas, eliminates the need for large-area lighting systems, makes full use of vertical space, and reduces the use of diesel and electric forklifts by replacing them with high-efficiency stacking cranes and transport belts.

Queen South Textile Mills LimitedWearing Apparel Manufacturing Industry

Adoption of high-speed computer winding machines

Replacing traditional slow-speed winding machines with high-speed computer winding machines, increasing energy efficiency and reducing energy consumption

Queen South Textile Mills LimitedWearing Apparel Manufacturing Industry

Adoption of infrared heating and servo motor in injection moulding

Changing injection moulding machines from horizontal to vertical style and replacing asynchronous motors with servo type motors, reducing electricity consumption by 13-26 per cent, saving 23,000-28,000 kWh per machine annually. In addition, infrared heating elements replaced traditional ones, saving 8,500 kWh per machine annually.

Positec Technology (China) Co., Ltd.Machinery, Equipment, Apparatus, Parts and Components Manufacturing Industry

Installation of energy saving rotisserie ovens

Installing rotisserie ovens with precise temperature control and uniform heat distribution. They have baking temperatures 15˚C lower than traditional ovens but produce the same result, reducing energy consumption by 30%. When comparing an electric oven, using natural gas as a fuel can lead to a reduction in carbon footprint by 32%.

Vesta Baking Solutions (SH) LimitedFood Manufacturing Industry