Best Practices

Compressed Air System

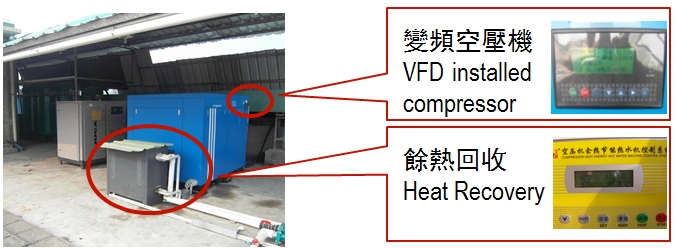

VFD air compressor and heat recovery

Installed a variable-frequency air compressor. The recovery of waste heat from the compressor provides a hot water supply to factory dormitories, saving 100,800 kWh or more than 30 percent of electricity and carbon emissions annually.

Spintec Precision (Shenzhen) Ltd.Fabricated Metal Industry

Air compressor – compensated capacitor

Adding a compensated capacitor to reduce the single phase current from 182A to 157A to save electricity and cost.

Leedarson Lighting Co., Ltd.Electrical Appliances and Houseware Industry

VFD Compressor

Air compressor: Installing VFD and heat recovery systems, using temperature-sensitive automatic ON/OFF controls in heat sinks.

Ningbo Daye Garden Machinery Co., Ltd.Machinery, equipment, apparatus, parts and components manufacturing

Variable speed screw air compressor with permanent magnet motor

Installing a variable speed screw air compressor with permanent magnet motor. This reduces energy loss when compared to belt-driven type. Electricity consumption is reduced by 40 per cent and 10 per cent respectively, when compared to traditional and variable speed air compressors. This feature has reduced electricity consumption by abut 40,000 kWh annually.

Nexus Electrical (Jiaxing) LimitedElectrical Appliances and Houseware Industry

Micro-computer automatic controlling system

Adopting a new micro-computer automatic controlling system in compressed air system, reducing electricity consumption by 20%.

Leo Group Co., Ltd.Machinery, Equipment, Apparatus and Components Industry

Variable frequency rotary screw compressor

By replacing their piston compressor with a variable frequency rotary screw compressor in knitting machines, the cycle time for changing the lubricant of the rotary screw compressor has been extended by 4 times versus the previous requirement. The usage of lubricant has also been reduced, resulting in a saving on annual electricity consumption of 15 per cent.

Super Performance Textile (Shenzhen) Co., Ltd.Wearing Apparel Manufacturing Industry

Centralized compressor

Adopting a centralised compressed air system to replace independent compressors, reducing electricity consumption by 110,000 kWh annually.

Foshan Longart Building Decoration Materials Co., Ltd.Building Materials Industry

Waste heat recovery from air compressor

Recovering waste heat from air compressors, transferring heat through insulation pipe and blower to tampo printing production area, replacing their original heaters and providing heat for drying printing ink, reducing annual electricity consumption by maximum 570,000 kWh and lowering carbon emissions by maximum 370 tonnes annually.

Ningbo Klite Electric Manufacture Co., Ltd.Electrical Appliances and Houseware Industry

Energy saving compressed air pipelines

Retro-fitting and using energy-saving aluminum alloy compressed air pipelines, shortening pipeline lengths and lowering output pressure, reducing electricity consumption by 20,000 kWh annually.

Chow Tai Fook Jewellery Park (Wuhan) Co., Ltd.Jewellery Industry

Pressure control device in compressed air system

Improving the pipeline distribution of compressed air system, installing compressed air pressure control devices and optimising system’s operating parameters, saving about 40,000 kWh of electricity consumption annually and resulting in carbon emissions reduction of about 26 tonnes annually.

Hop Yick Bangladesh LimitedWearing Apparel Manufacturing Industry

Installation of automatic drain valves in air receivers of air compressor

Installing automatic drain valves in air receivers of air compressor. These automatically remove condensate, improve energy efficiency, protect system components from moisture-related damage, and lower electricity consumption by 1,738 kWh per year.

Cerie (Cambodia) Garment Co., Ltd.Wearing Apparel Manufacturing Industry